Flow Measurement & Control

Mass Flow Meter, Digital High Performance with Multiple Gas Capability (Dial-A-Gas®). For flow ranges from 0 to 10 sccm to 0-1000 slpm.

For flow ranges under 4 sccm (smlm) with a minimum controllable mass flow rate of 0.1 sccm (smlm).

High application flexibility and stable long term accuracy for any gas, including toxics and corrosives.

For measurement and control of any clean, dry gas mass flow from 10 to 1000 SLPM, with lower flows and higher flows available upon request.

For precision gas mass flow control of expensive process gases, where minimal pressure drop is a key consideration for cost savings and efficiency.

Ideal for process monitoring, gas blending and flow calibration applications among many others.

For measurement of air and ALL inert gases & mixtures in flow ranges from 0-10 sccm up to 0-50 slpm.

Economical Analog Mass Flow Controller for flow ranges from 0-10 sccm to 0-50 slpm.

Mass or volumetric flow monitoring of gases, liquids and steam and a compact, low-cost alternative to Coriolis meters.

Ideal for wastewater treatment applications, hazardous areas, facilities management, and general process control applications where high accuracy is critical.

Ideal meter for measuring gas flow in cramped or constrained piping environments where long straight pipe runs simply do not exist.

For chlorine injection processes found in typical waste-water treatment applications.

High accuracy portable clamp-on ultrasonic liquid flow meter.

High accuracy transit-time ultrasonic liquid flow meter with thermal energy/BTU capability.

For compressed air flow, aeration basin air flow, combustion air flow, natural gas fuel flow, custody transfer and stack gas emissions flow monitoring.

Ideal for custody transfer, wastewater treatment, hazardous areas, facilities management and general process control applications where high accuracy is critical.

For light industrial applications where a NEMA 4X (IP65) enclosure is acceptable.

For precise natural gas measurement to heaters and boilers to increase efficiency.

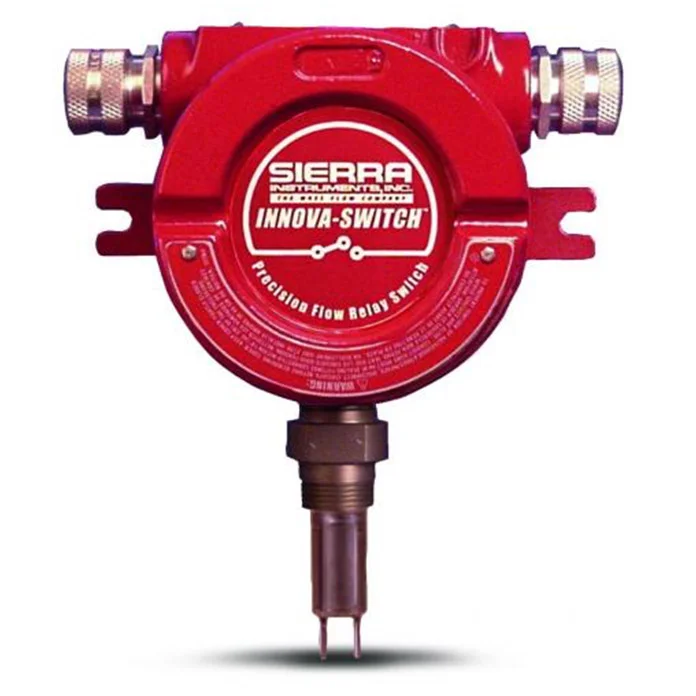

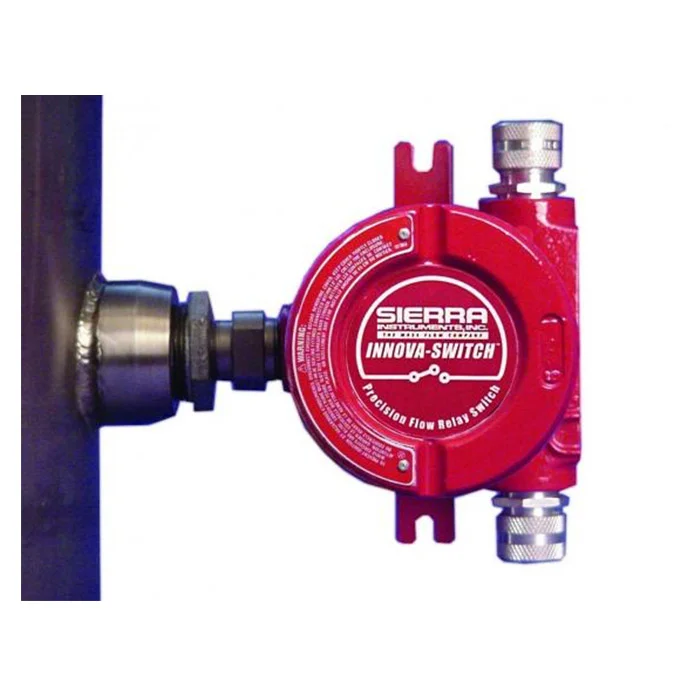

Mass flow switch for the detection of the mass flow rate of liquids and gases.

Liquid Level Switch for the detection of the liquid level in tanks and process vessels.

For a constant density input to calculate mass flow for incompressible fluids or constant density gas or steam flow.

Large pipe applications, high pressure applications and numerous geothermal steam applications.

The Badger Meter RCT1000 Coriolis mass flow meter identifies flow rate by directly measuring fluid mass over a wide range of temperatures with a high degree of accuracy.

For non-intrusive flow and energy measurement applications

For non-intrusive flow measurement of liquids with sonic reflectors.

For non-intrusive flow velocity assessments in closed-pipe systems.

This portable meter has transducers that clamp onto the outside of the pipe – no tapping or cutting is required.

For food, beverage and pharmaceutical applications.

For food, beverage and pharmaceutical applications.

An innovator in flow measurement and control products, Badger Meter serves water utilities, municipalities, and commercial and industrial customers worldwide. Measuring water, oil, chemicals, and other fluids, Badger Meter products are known for accuracy, long-lasting durability and for providing valuable and timely measurement data.

Dynasonics products are used to measure and control the flow of liquids, including water, oil and chemicals, and are known for accuracy, long-lasting durability and for providing valuable and timely measurement data.

Badger Meter offers the Blancett® family of turbine flow meters to measure everything from water in hydraulic fracturing and mining operations, to gases and liquids from wellheads, and various fluids in sanitary environments.

Since the introduction of the Hedland Variable Area Flow Meter for hydraulic oil, our product line has grown to over 15,000 flow meter models including, turbines, switches and transmitters. We provide cost effective flow measurement in the following applications: oil, phosphate esters, water, water-based fluids, air, and other compressed gases.

Preso Differential Meters offer a custom engineered solution specifically manufactured to fit within your system. This technology offers a reliable long term solution for fluid, steam or gas applications. Preso can provide a flow meter for any process that can be measured with differential pressure technology, often at calibrated accuracy of better than +/- 0.5% of reading.

Whether it’s improving accuracy, decreasing system maintenance or meeting the demands of challenging liquid conditions, Badger Meter Electromagnetic Meters deliver the performance your critical flow measurement applications require.

The Badger Meter RCT1000 Coriolis Mass Flow Meter identifies flow rate by directly measuring fluid mass over a wide range of temperatures with a high degree of accuracy. For fluids consisting of two liquids or gases, the RCT1000 Coriolis system can derive the concentration and mass of each fluid based on the density measurement.

Processing plants, research facilities and government agencies worldwide rely on Research Control® Valves from Badger Meter for repeatable performance and durability. Built for applications two inches or smaller, our globe, angle and sanitary valves are integral components in systems ranging from petrochemical processing to pharmaceutical manufacturing.

Badger Meter Industrial Oval Gear meters are designed to function in applications that require an accurate volume dispensing of water solutions or any other liquid. These products have rugged, shock-resistant plastic covers, similar to those used for power tools, protecting the meters from harsh and demanding environments.

Innovative high-performance fluid flow measurement and control instrumentation for nearly any gas, liquid and steam application spanning across global industries as diverse as scientific research, semiconductor, wastewater treatment, iron and steel, clean energy, aerospace and biotech to name a few.

For applications where liquid conditions tend to damage or impede mechanical flow meter operation.