Blancett

/Badger Meter offers the Blancett® family of turbine flow meters to measure everything from water in hydraulic fracturing and mining operations, to gases and liquids from wellheads, and various fluids in sanitary environments. Our turbine meters deliver accurate, consistent, reliable and informative flow measurements for both liquid and gas applications.

- High-performance materials of construction: 316L and CD4CMU stainless steel, tungsten carbide

- Hazardous area or explosion-proof certifications for industrial and petrochemical installations

- Easy-to-operate electronics

- Customized features for unique applications

- Compatibility, retrofit capability with other manufacturers

- Calibration to NIST-traceable standards

Products & Accessories

- Flow Meters

- Flow Monitors

- Electronic Accessories

- Repair Kits

Compatible with most low-viscosity liquids and natural gas, Blancett meters are suitable for a wide variety of applications in upstream oil and gas, food and beverage, petrochemical, semiconductor, and irrigation. The meters provide cost-effective solutions for general area, hazardous area or 3-A sanitary applications.

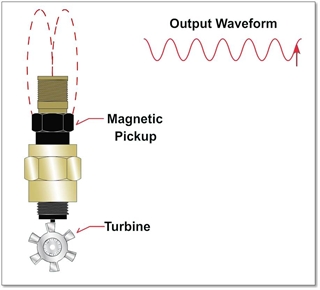

The Blancett family is offered with an assortment of accessories for local flow or totalizer indication, and delivers output signals to suit the inputs required by data acquisition or control systems. Available accessories include local monitors, frequency-to-analog transmitters, and frequency-to-square wave transmitters. A varied selection of turbine meter pickups is also offered to meet application requirements.

Committed to fast deliveries, Badger Meter maintains a factory lead time of five days for standard Blancett configurations. Expedite options are also available. All Blancett flow meters, attached transmitters, and repair kits receive a five-point, NIST-traceable calibration as standard.

Application Example

Blancett Meters Help Hydraulic Fracturing Companies Keep the Environment Safe and Meet Government Regulations

Hydraulic fracturing, also known as fracking, is a process used to extract underground natural resources from below the Earth’s surface. These resources include oil, natural gas, geothermal energy, and even water. The process includes pumping fracturing fluid at high pressures into a well, sometimes drilled thousands of feet deep. The pressure of the fluid creates cracks in the underground rock, allowing trapped resources to flow up the well.

Since the fracturing fluid contains chemicals and consumes water, companies are required by state and federal law to maintain accurate records of process fluid injected into and recovered from wells. The laws help ensure environmental and public safety.

With high accuracy and a rugged design, Blancett 1100 Series meters in six, eight and 10 inch line sizes are an ideal solution for measuring process liquid in hydraulic fracturing operations in the U.S. and Canada; often mounted on the pump trucks that deliver and recover the process water. Blancett meters maintain high accuracy while withstanding on-truck vibration and harsh conditions.

Additionally, the Blancett B3000 monitor can be used with the 1100 Series meters to provide customers with a durable, easy-to-use meter interface, which simultaneously displays flow rate and flow total. The B3000 allows for greater control and visibility of flow with features such as alarm parameters, advanced connectivity options and a variety of mounting options.